Exploring Viking Pump's Foundry: A Leader in Manufacturing Gear Pumps

04-14-2025

Welcome to the Viking Pump foundry in Cedar Falls, Iowa, where we’ve been at the forefront of manufacturing gear pumps for decades. Our foundry is a cornerstone of our vertical integration capabilities, allowing us to produce castings and parts at speed.

Robyn Watson

Sr. Marketing Coordinator

Universal Mag Drive, The Sealless Upgrade That Prevents Leakage and Fugitive Emissions

5 minutes

03-25-2025

Viking Pump invented, patented and manufactured the very first sealless mag drive rotary positive displacement (PD) pumps in the world, and developed several series over time for different applications, including the first generation 825, 895 and 855 ™ internal gear pumps.

Of these first generation mag drive pumps, all had different footprints from their…

John Hall

Pump Consultant

Four Ways to Source Hygienic Pumps

01-07-2025

There are really four main types of suppliers of hygienic, or sanitary pumps for food and pharmaceutical applications. There is no…

Revolutionary to Evolutionary: A brief history of the Viking Pump® internal gear pump

12-23-2024

In the early 20th century industrial innovation was accelerating. And as Henry Ford developed his Model T and the Wright Brothers were unlocking the secrets to manned flight, a Danish immigrant named Jens Nielsen was working on an invention of his own. Nielsen’s internal gear pump was intended to be used to lift water from his quarry but soon others found uses for his pump…

Chad Wunderlich

Distributor Development Manager

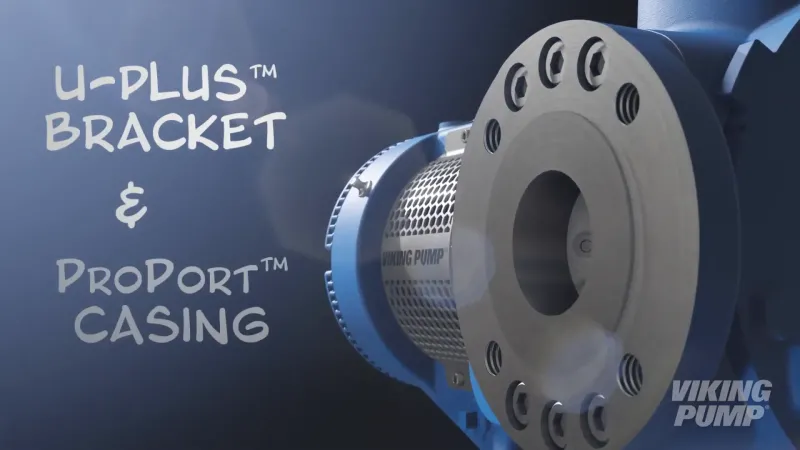

Exploring the Versatility of the U-Plus™ Bracket and ProPort™ Casing in Gear Pumps

01-21-2025

At Viking Pump, innovation is at the forefront of what we do. With the introduction of the U-Plus™ Bracket and ProPort™ Casing, we are redefining the capabilities of our internal gear pumps. These advancements are not just about new technology; they are about providing flexibility…

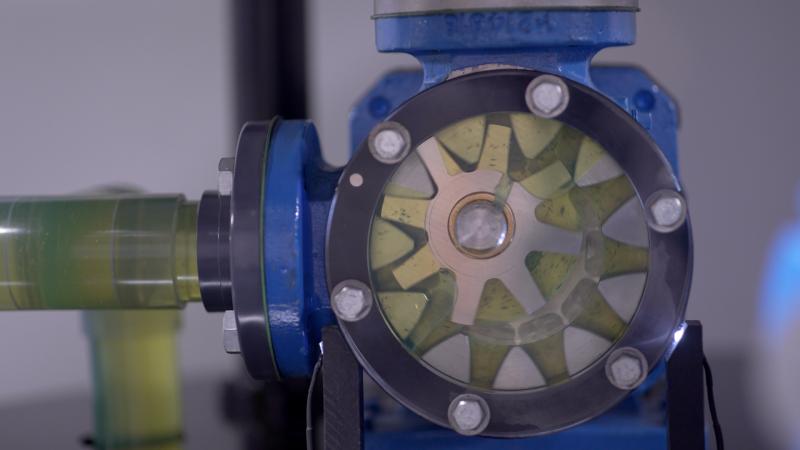

Understanding Internal Gear Pumps: How They Work and Their Benefits

11-19-2024

Discover how internal gear pumps work, their key features, and their advantages across various industries. Learn why they're the preferred choice for fluid handling.

John Hall

Pump Consultant

All You Need to Know About ProPort™ Casings

11-14-2024

Viking Pump’s new generation of internal gear pumps offer a wide array of benefits that the previous alloy pumps could not, particularly in the area of porting flexibility. These new pumps reduced the number of casing configurations, which helps reduce manufacturing complexity, cost and lead times, while at…

John Hall

Pump Consultant

Introducing Viking Pump’s NEW Generation of Pumps

11-14-2024

As a masterclass in engineering design and manufacturing flexibility, Viking Pump has re-designed its heavy-duty alloy pumps, both steel and stainless steel, in the most ingenious ways. These new models reduce price and lead time by significantly reducing the number of casings and brackets for manufacturing simplification, while simultaneously providing more options for porting and shaft…

John Hall

Pump Consultant

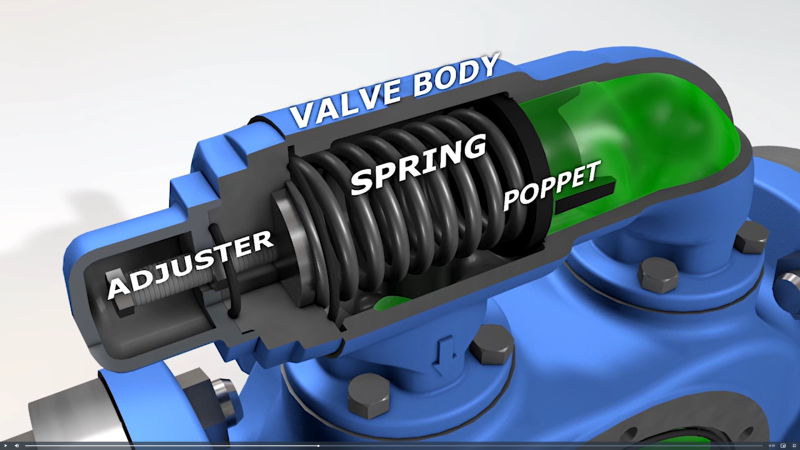

Pressure Relief Valves: Critical to Pump and System Safety and Reliability

01-26-2024

A key advantage of rotary positive displacement pumps is providing consistent flow regardless of changes in liquid viscosity or differential pressure. But should a downstream blockage occur, pressure will rapidly build and may exceed the rating of the pump, drive equipment, system, or any combination thereof, with the potential for damage and unplanned downtime. For this reason, overpressure…

John Hall

Pump Consultant

How An Internal Gear Pump Works

01-09-2024

All positive displacement pumps work by first expanding a cavity between the casing and one or more moving parts to create a partial vacuum, so atmospheric pressure can force liquid into the pumping chamber through the inlet port

John Hall

Pump Consultant